Column2

Column 2:

The Japan Society of Applied Physics (JSAP): 1

Sales Director at Systems Engineering Inc.Toshihiro Takata

Dr. Tatsuo Uchida delivered a commemorative speech at the 70th JSAP Spring Meeting 2023 as a JSAP Outstanding Achievement Award recipient. He gave a comprehensible speech that seems easy to understand even for young people about the history of R&D and industrialization of liquid crystal technology whose domestic production achieved a peak about 20 years ago. Listening to his speech reminded me, for the first time in a while, of the fact the liquid crystal technology was originated in Japan.

Dr. Uchida has achieved results not only in the research area of the liquid crystal technology but also its industrialization. The technologies he has developed are indispensable for the current LCD (liquid crystal display) production. They have been continuously handed on to the next generations at production sites in Japan and abroad and are rightfully assembled in our television sets. Dr. Uchida, based in Tohoku University in Sendai, the City of Trees, supported the advancement of liquid crystal technology from a scientific perspective in its early days through to the period of growth. I know very well that he communicated actively with corporate researchers and conducted continuous researches / experiments from the days when commercialization of LCD was still uncertain.

The following are the part of his research achievements:

・Additive color mixture of RGB color filter

・Technological enhancement of response speed and viewing angle, mechanism elucidation of molecular orientation of liquid crystal, especially mutual interaction of rubbed polyimide film and liquid crystal molecules

・Reflective LCD

・Liquid crystal of OCB(optical compensated bend) type

Liquid crystal technology started with laptop word processors during the last decade of the 20th century and they developed into notebook computers. Around the same time, electronic diaries, handheld gaming devices, and mobile phones began to spread. Then LCD TVs appeared at the dawn of the 21st century and drove CRT-based televisions away from households. Now we find this technology in smartphones. I do have a SONY Trinitron 37inch High Vision (high-definition television) and it is still working after replacement of substrate.

Expansion and penetration of LCD technology promoted digitalization of paper-based records and changed our lifestyle and way of working dramatically. This reminds me of the significant change in the area of photography.

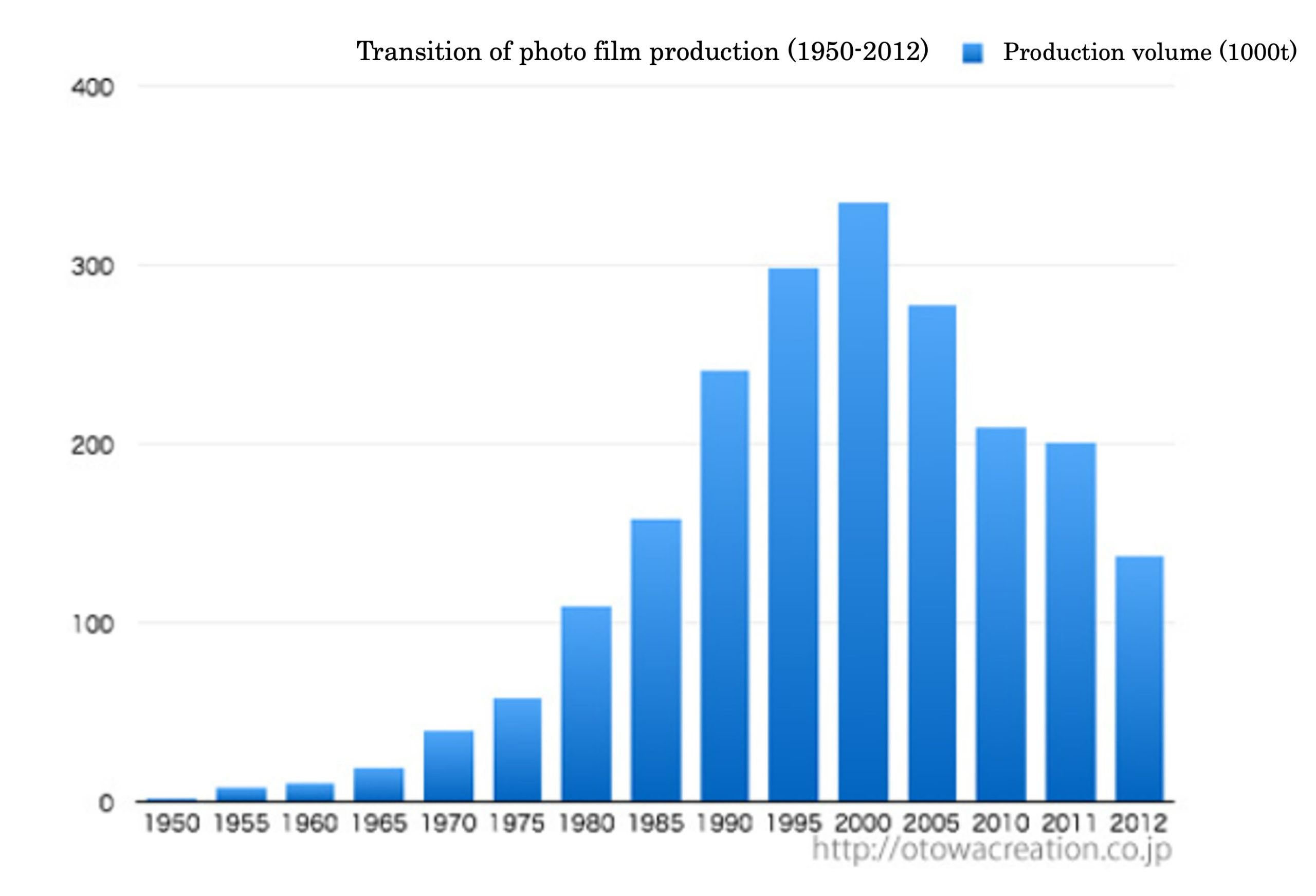

Digitalization of cameras has been dwindling the photo film market.

Its downward trend is shown in the following graph.

I myself have not purchased a photo film for a decade or so.

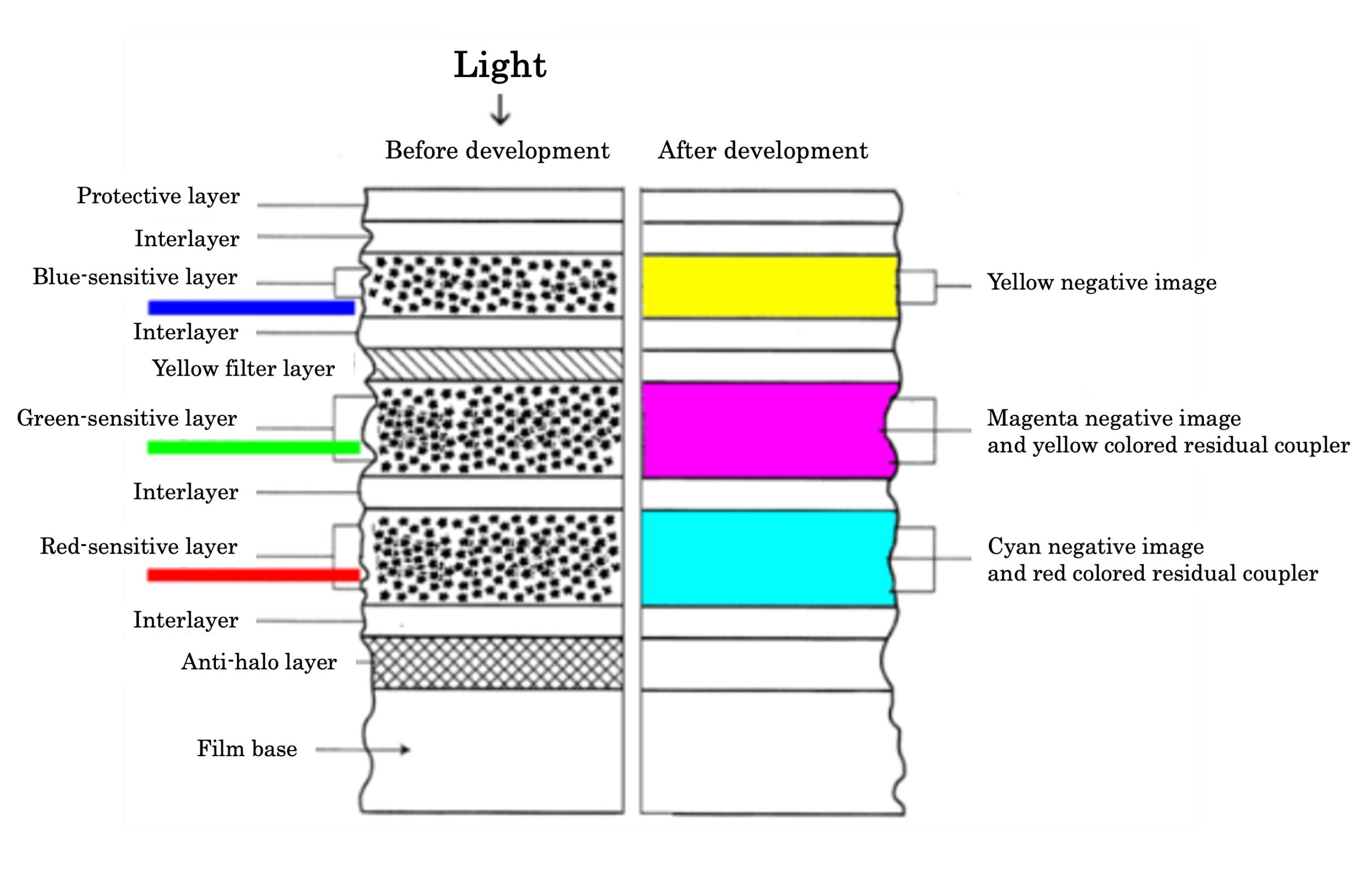

Curiously enough, however, TAC (tri acetyl cellulose), a base material for a photo film, contributes greatly to liquid crystal technology. What is TAC?

TAC has the characteristics of non-flammability, transparency, electrical insulation, and above all, no birefringence. A liquid crystal panel needs to control polarization and therefore to use base material without birefringence. In case of a photo film, many necessary functions are formed to be layers in order with accuracy as designed, and its film base is required to be a material without optical property (birefringence). The material of this photo film base, TAC, was found to be highly suitable as a base material for LCD.

Accordingly, TAC was adopted to make a polarizer of LCD in high volume. FUJIFILM, Konica (currently Konica Minolta) and Kodak used to be dominant producers of photo films, and now FUJIFILM and Konica monopolize the world market of TAC for LCD.

As you can see from the case of photo films, a significant growth of Japanese LCD industry was brought about by Japanese industrial structure of that time, let alone the fruitful R&D itself. LCD is composed of numerous parts whose supply chains were functioning well in Japan.

* Glasses for LCD

* Color filter

* Black matrix

* Forming and rubbing of alignment film

* Retardation film, polarizer

* Light guide panel, diffuser panel

* Materials for liquid crystal

* ITO film

* Forming of TFT

* Glass bonding and filling/sealing of liquid crystal

The supply chains of these LCD parts are fully completed within Japan. Apart from the raw material procurement, having almost all the necessary processing technologies domestically has contributed to the creation of the efficient production system of LCD in Japan. This is impossible in other countries. One matter for concern is that many of the films in LCD use minerals — indium, a material of the ITO film, for example, is a by-product of processing a mineral, and 70% of its output is produced by China and Korea — and their supply is greatly influenced by political circumstances. It is a favorable tendency that its recycling rate has been increasing to about 60% in these years. Japan uses the most indium in the world, and at the same time, Japanese manufacturing technology for ITO film is the world’s best. Therefore, China and Korea, accelerating the production of LCD panels and solar cells, have no option but to be incorporated into and comply with the supply chain in Japan. Although a large part of the LCD panel assembly has been transferred to Asian countries, it is Japanese manufacturers that supply its components. Japanese fabulous producing/processing technologies that generate excellent components make this possible.

The semiconductor industry has so the called silicon cycle, so its booming period will come again. However, production of LCD would never come back to Japan. That would be the case with OLED (organic light emitting device/display), LED TVs and laser TVs, and there is no room for doubt that most part of FPD productions will remain in Asian countries. We have to consider the fact that the production output of liquid crystal panels, a technology of Japanese origin, has been dramatically decreased, and that the Japanese top manufacturers of liquid crystal panels got passed by foreign manufacturers so easily, their related businesses collapsed a few years ago and are preserved under Chinese capital. How come the glorious story of LCD application from calculators to televisions, that started just a little over ten years ago, would have faced such a sad ending? After that, the LED technology that Japanese researchers were awarded Nobel Prize for blossomed in Japan and then got transferred overseas in a shorter period of time than LCD panel. What is the problem in the fact that cutting-edge technologies are being transferred overseas so easily?

Those who have been in the industrial world for a long time feel a deep responsibility to develop the next new technology for the sake of Japan in a way it truly contributes to the affluence of Japanese people. People without the knowledge of our country’s past experience might not realize that preventing technology leakage is more important than gaining money temporarily. Why don’t we experienced people in the industry do as much as we can?

→Continued on “The Japan Society of Applied Physics (JSAP): 2”

Trackbacks and Pingbacks on this post

No trackbacks.

- TrackBack URL

Comments on this post