3:

Non-destructive testing

What is to be achieved with this technology

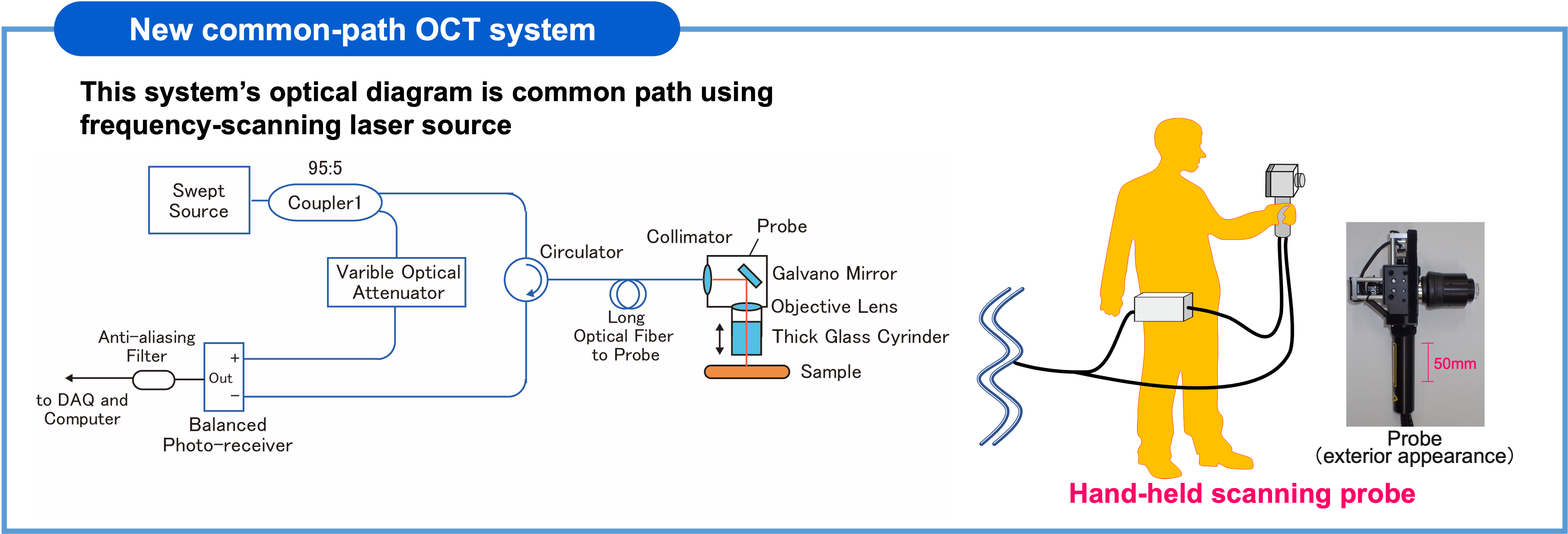

OCT has been developed as a medical diagnostic technology. In order to apply this technology to industrial products, we tried to improve its versatility so that it could be used in production sites; accordingly we have designed unique OCT system based on new optical scheme.

Using our unique optical design and detector technology, we have realized a system that can directly scan large-size samples such as tanks and pipes (at their construction sites) at a high resolution as accurate as laboratory level.

Practical example:Characteristics of common-path OCT(CP-OCT)

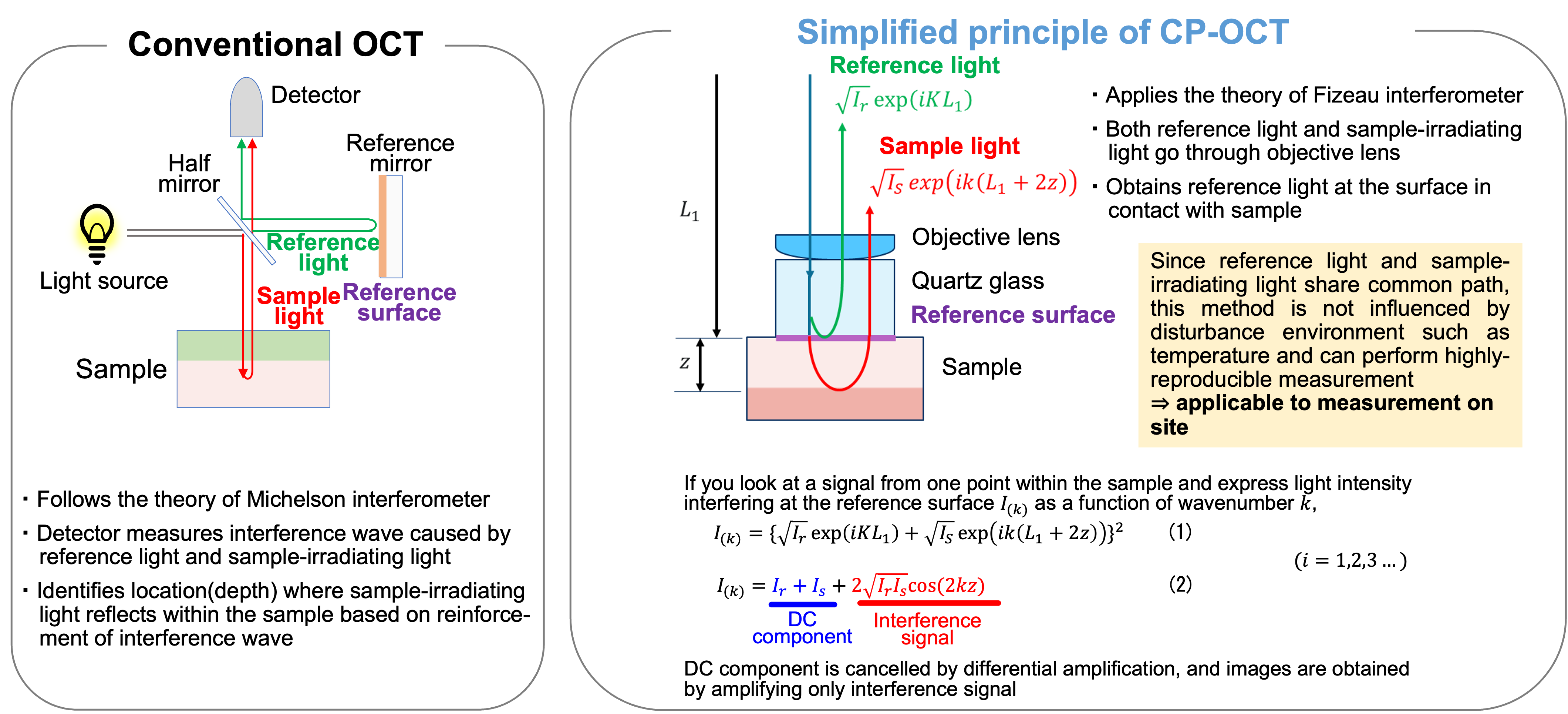

OCT is a technology that measures traveling range of light using its coherency. When you irradiate measuring object with near-infrared light and couple its scattered light and reference light that returns through fixed path, interfering light signal will be produced. By detecting the signal, tomographic images in depth can be obtained.

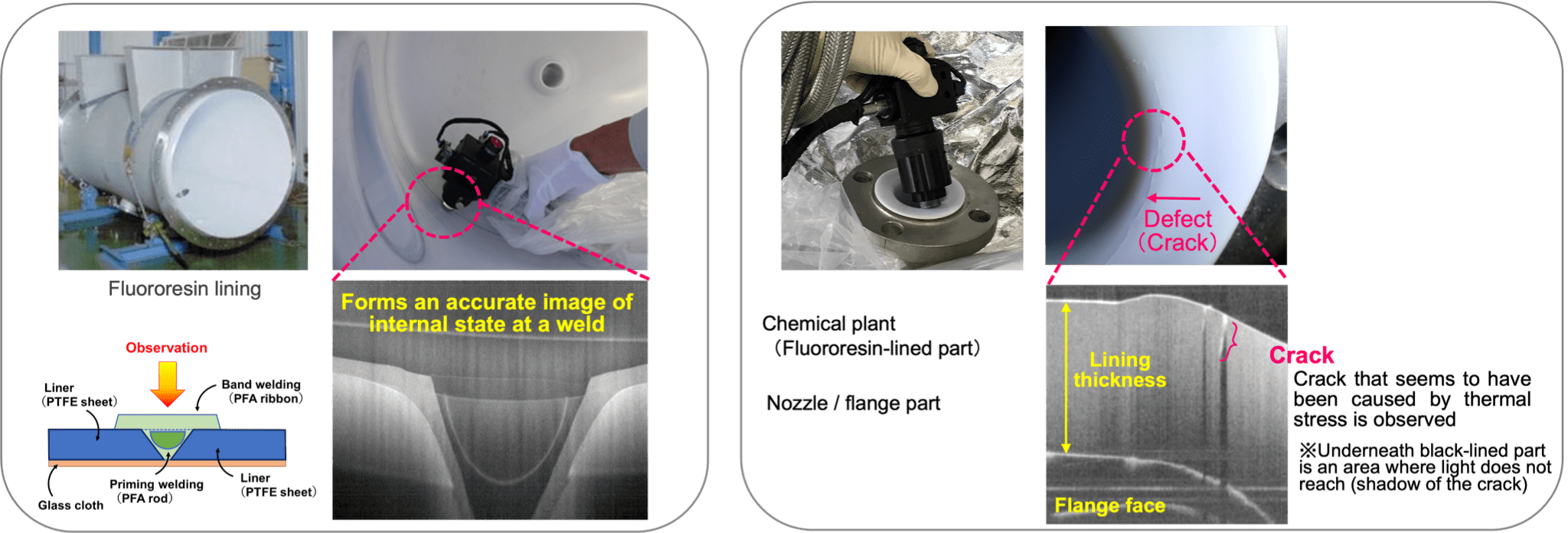

Practical example:Detecting site and detection result

Application to resin-lined equipment: Fluororesin is the most suitable corrosion-proof lining material for chemical process equipment because of its outstanding corrosion resistance and thermostability. However, under long-term harsh environment in which an equipment is exposed to highly acid chemical, high temperature, and/or high pressure, damages such as blister, delamination, crack, or pinhole at welds would occur. Therefore, periodic relining and maintenance are required.

OCT can visualize parts that were difficult to check with conventional detectors; base material under coating film, buried interface/junction, and so on. Digitization of internal microstructure enables testing regardless of inspector’s skill or sensibility. Obtained image data can be utilized in aging diagnostic system and deliberate repair/replacement of equipment.

Practical example: Prototype specification, range of use and application, future prospects

We have realized sophisticated module design that can be optimized for various applications with arbitrary condition setting of wavelength, image resolution, and data acquisition rate. This enables augmentation of imaging function by corresponding with special needs/demands in accordance with site environment and data application. OCT has a high affinity for information deep leaning because it is an imaging technology based on light propagation and physical properties of materials. In order to further broaden the system’s utilization and application, we are advancing the development of this innovative non-destructive testing solution by introducing support from AI.